Quality

Quality

Quality Policy:

Produce solutions in steel parts for the global industry, continuously improving processes, aiming to satisfy Stakeholders.

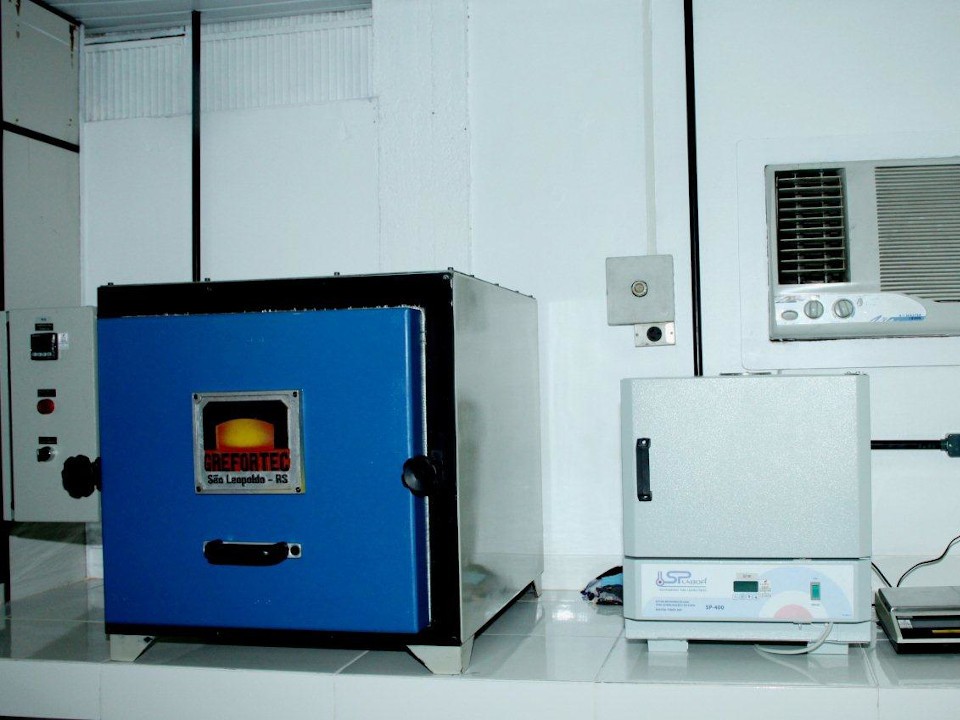

Laboratory: The quality control team at Qualisteel Investment Casting has two laboratories for conducting tests and analyses that certify the quality of manufactured products according to the traceability needs of each client, adhering to international quality standards.

Product Tests:

- Liquid Penetrants: detects leaks in parts;

- Mechanical Properties Testing (Tensile/Hardness): tests that certify the effectiveness of heat treatment and the mechanical properties of the material;

- Dimensional: generally conducted on a sample of prototypes before the entire series of parts is cast;

- Chemical: includes chemical analysis to determine each alloy;

- Visual: visual inspection to detect possible defects arising from the manufacturing process, as well as detecting internal defects with ultrasound;

- Outsourced tests: (e.g., Magnetic Particles (Magna Flux) and X-Ray).

Raw Material Tests:

- Drop Point: test applied to waxes and their components. Checks the melting/softening point of the wax;

- Ash Content: determines the ash content of wax, rosin, and similar materials. Ash content is defined as the weight percentage of the residue after complete combustion;

- Moisture Content: determines the moisture content (in percentage) of inputs by eliminating water through controlled heating, checking the difference in mass;

- pH: determines the pH value of raw materials and products from the process;

- Colloidal Silica Content: describes the method of controlling silica content as a raw material;

- Gelation of Baths: evaluates the quality of the binder, determined by accelerating the conditions of ambient temperature;

- Density: measures the density of colloidal silica as a raw material and in the baths;

- Linear Shrinkage: linear shrinkage test of the wax after being released for injection;

- Dry Granulometry: determines the dry granulometric percentage of sands, clays, and chamottes used in the coating process;

- Wet Granulometry: determines the wet granulometry of raw materials used in the coating process.